|

Products |

Home > About QSC

Carbon Steel Wire*

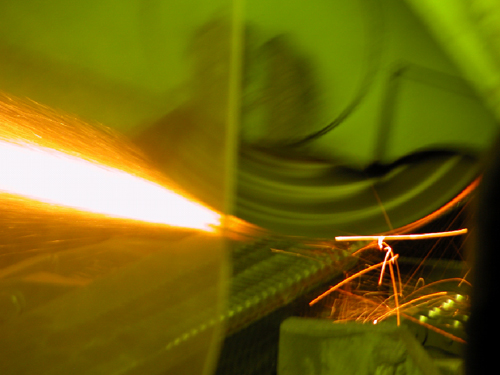

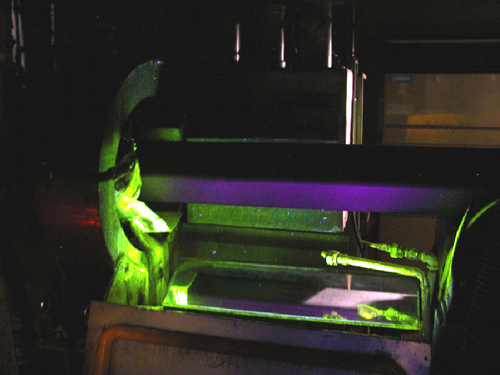

►Product Introduction With the best quality billets we purchased from the most famous mills world wide, our hot rolled wire rod products are specialized in low carbon steel, high carbon steel, low alloy steel and free cutting steel, etc. ►Factory Information Foundation :January 1995 Annual Capacity :400,000 Tons / Year Numbers of Staff :250 Feature :About 236,000 Square Meters Feature : •Grinding equipment for surface quality improvement. •Walking beam type of reheating furnace for uniformity. •Two strands high speed rolling Coil weight up to 2 tons. Billet conditioning facility is a key feature of this plant. All of our billet must go through the detecting and grinding process before being rolled into the wire rods for assuring the surface quality. Brief History : 1995:Quintain Plant Founded 1997:Commercial Run of Wire Rolling Mill Commercial Run of Billet Conditioning Line 1999:Accredited ISO-9002 Quality System Accredited CNLA Laboratory Certificate 2006:Accredited TAF Certificate of Deformed Bars in Coil"Chiai Industrial Co., Ltd." changed the name to "Quintain Steel Co., Ltd." Address: 4F, NO.47, Xinjian Rd., South Dist.,Tainan City 70255, Taiwan Tel. : 886-6-2643888 Fax. : 886-6-2647188 ►Product Specification WIRE RODS STEEL GRADE: 1.Low Carbon Steel Wire Rods(Rimmed Steel) 2.Carbon Steel Wire Rods(Aluminum Killed Steel / Silicon Killed Steel) 3.High Carbon Steel Wire Rods 4.Low Alloy Steel Wire Rods 5.Low Carbon Steel Wire Rods(Silicon Killed Steel) 6.Free Cutting Steel Wire Rods 7.Carbon Steels For Machine Structure Use 8.Steel Bars For Concrete Reinforcement ( In Coil ) Wire Rods Standard Diameter: Ø5.5mm、 Ø6.5mm、 Ø7.0mm、 Ø8.0mm、 Ø9.0mm、 Ø10.0mm、 Ø11.0mm、 Ø12.0mm、 Ø13.0mm、 Ø14.0mm、 Ø15.0mm、 Ø16.0mm 。 Concrete Reinforcement ( In Coil ) Standard Diameter:#3 (D10) 、 #4 (D13)。 Download : Product Specification(PDF) ►Main Facilities

Customer Service Provides satisfaction the service is we greatest achievement

|